|

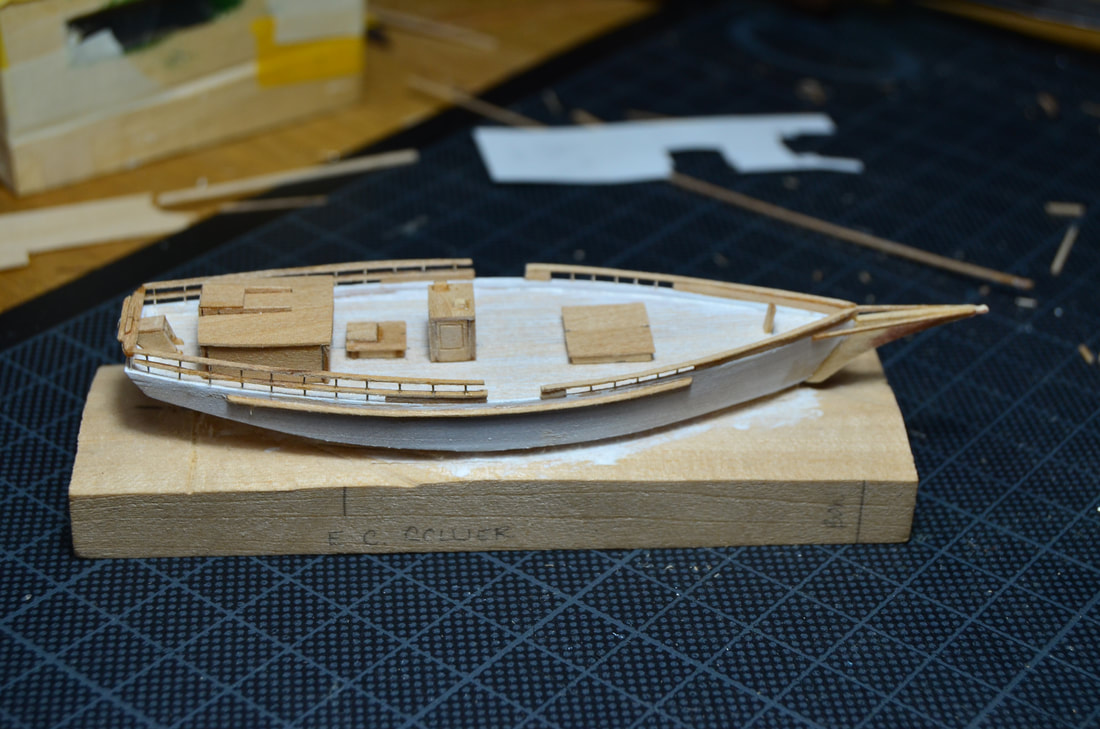

Things are warming up and new projects are rolling into the boatyard. On a nice day, I can even open the windows and hear the birds chipping. Yes Spring is near! With a few other projects occupying my time work has slowed on my Chesapeake scene, but it is always on my mind, and I manage to squeeze in a little work while paint dries on other projects. The Skipjack E. Collier is nearly ready to set sail...that is, as soon as I get her jib hoisted, but she looks mighty fine. With a brand new coat of red bottom paint she was ready to be cut from the block of wood out of which she was carved. That's right, there are no special tools here, just a handy japanese pull saw, and a good eye. Then it was up with her mast and massive main sail. The mainsail is made out of a fine linen material, which I stain with polyurethane to suit. Unlike using coffee, I can stain certain areas lighter or darker, by applying more or less stain with a brush. This creates the weathered appearance of the old cotton sails that dirtied easily. Next, I sewed on each mast hoop, and threaded all those reefing lines. The foot of the sail is lashed down through fittings on the boom. Another unique detail of the Skipjack, and I imagine quite practical is the lazy jacks. These are a web of lines that run down from a block at the top of the mast and finish at the boom. This kept the sail from falling all over the deck with the crew lowered it. I even found the time to fabricate the dredge, and prep the trailing boards. The rollers are installed for running out the dredging lines, the jib track is in place, and her capstan secured to the sampson post...she'll be ready for drudgin' 'fore ya know it! But let's move on! The Collier wasn't the only one to receive some well deserved attention. I made some nice advances on the Ferdinand Desoto Crockett (to use her full name). She too got a a couple coats of the classic red bottom paint before being cut from her block of wood. After a fresh coat of paint on the deck, the cabins and hatches,were installed. I also added all the doors to the pilot house, and even achieved raised paneling by applying thin archival paper before painting them white. Her spars were turned out of bamboo and I fixed up the boom jaw to fit nicely around the mast. She almost looks too pretty to be a work boat! She still needs a little work on her rigging and some of the addition features like trailing boards and her flag staff, but in no time fast, she'll be hauling oysters and making her pay. I still haven't been able to find time to start carving the bugeye...looks like my winter project is gonna roll over into the Spring, but all in good time. She'll be coming along shortly...as soon as I get some of those other projects out of the way!

Thanks for visiting!

5 Comments

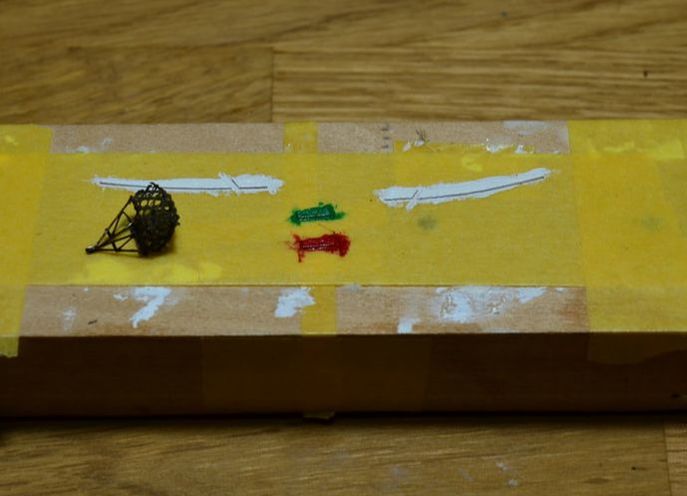

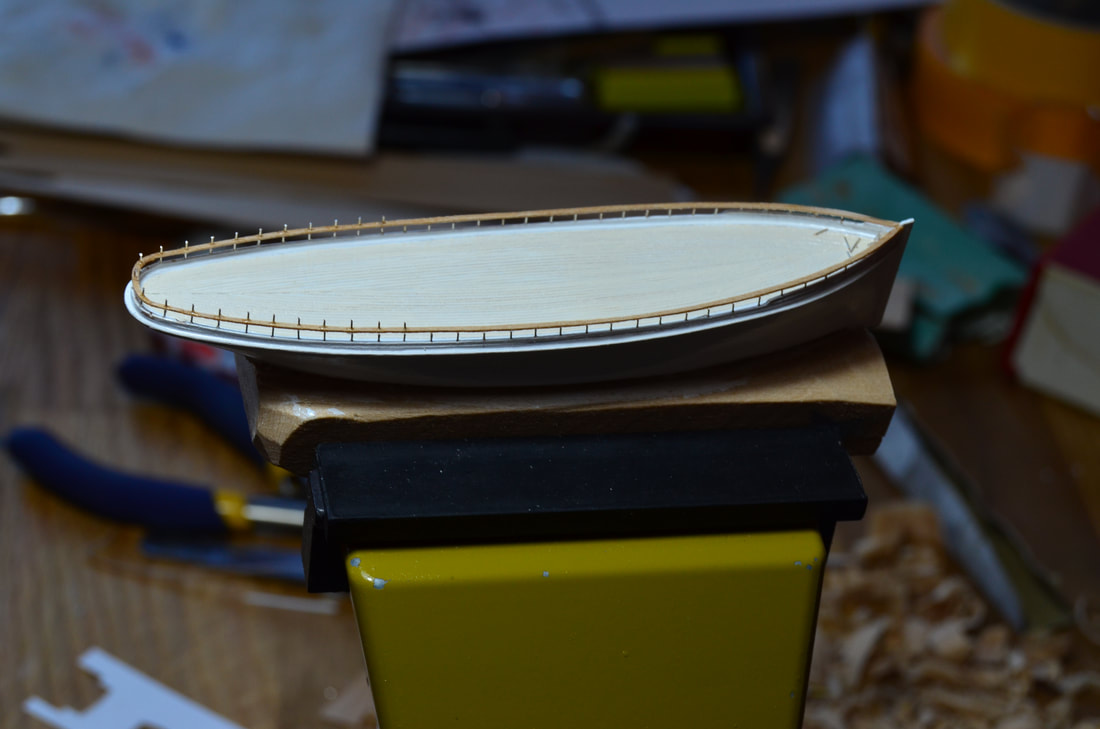

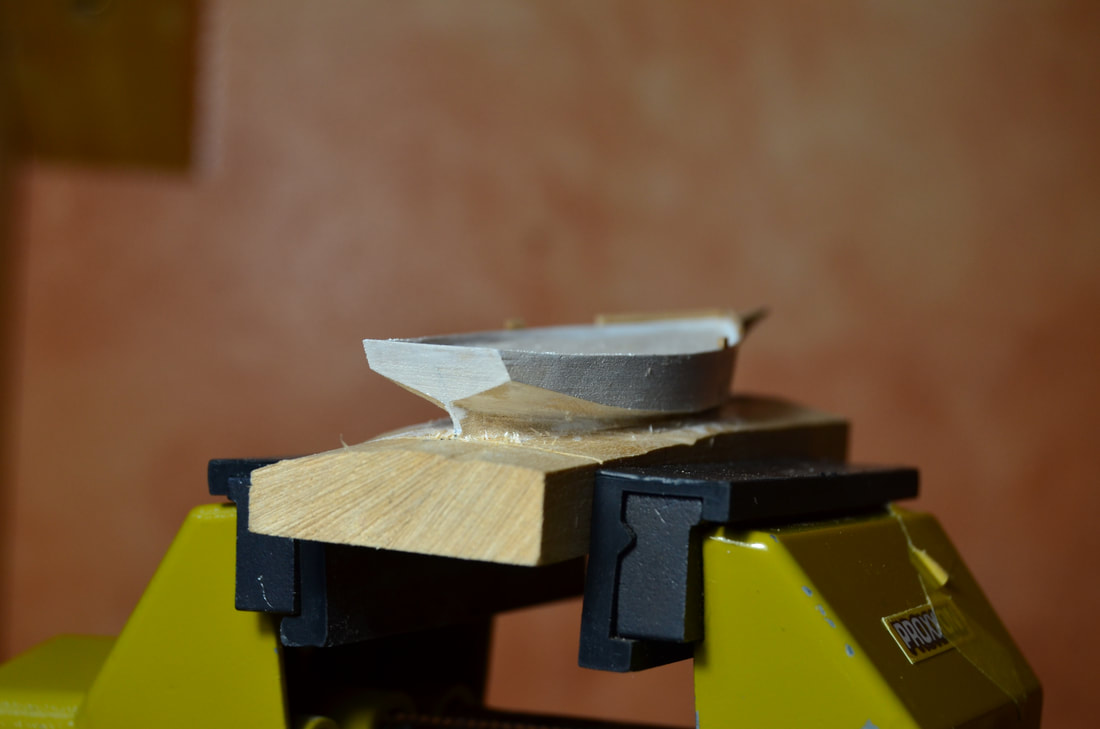

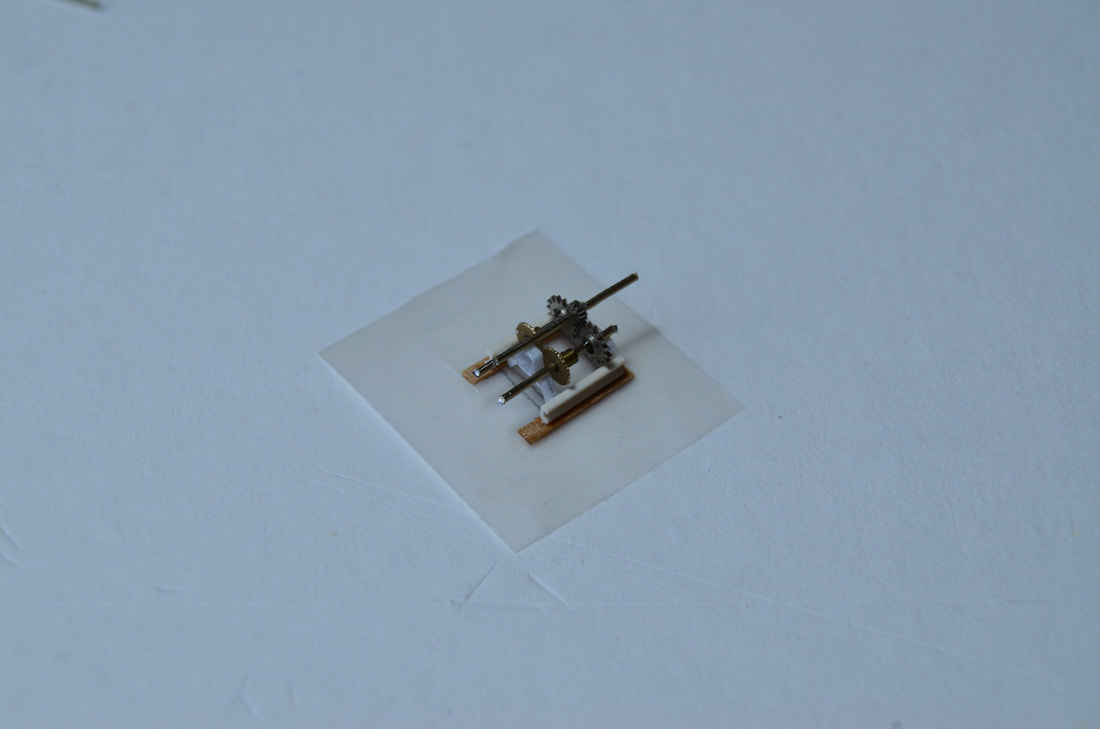

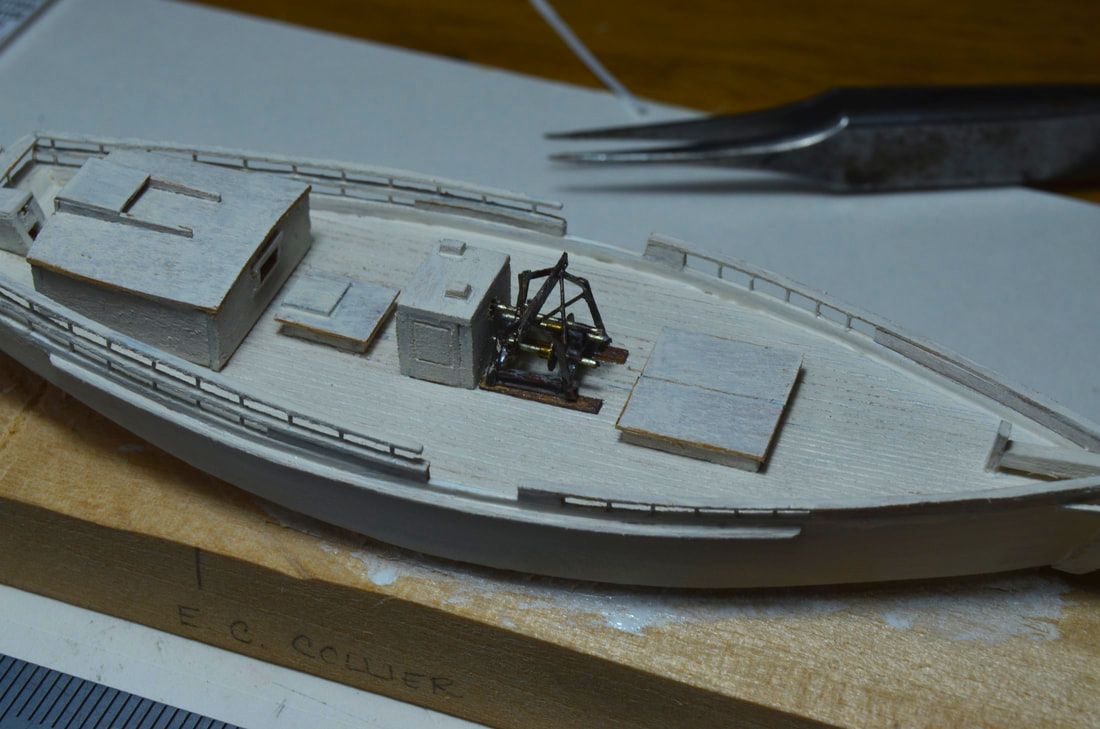

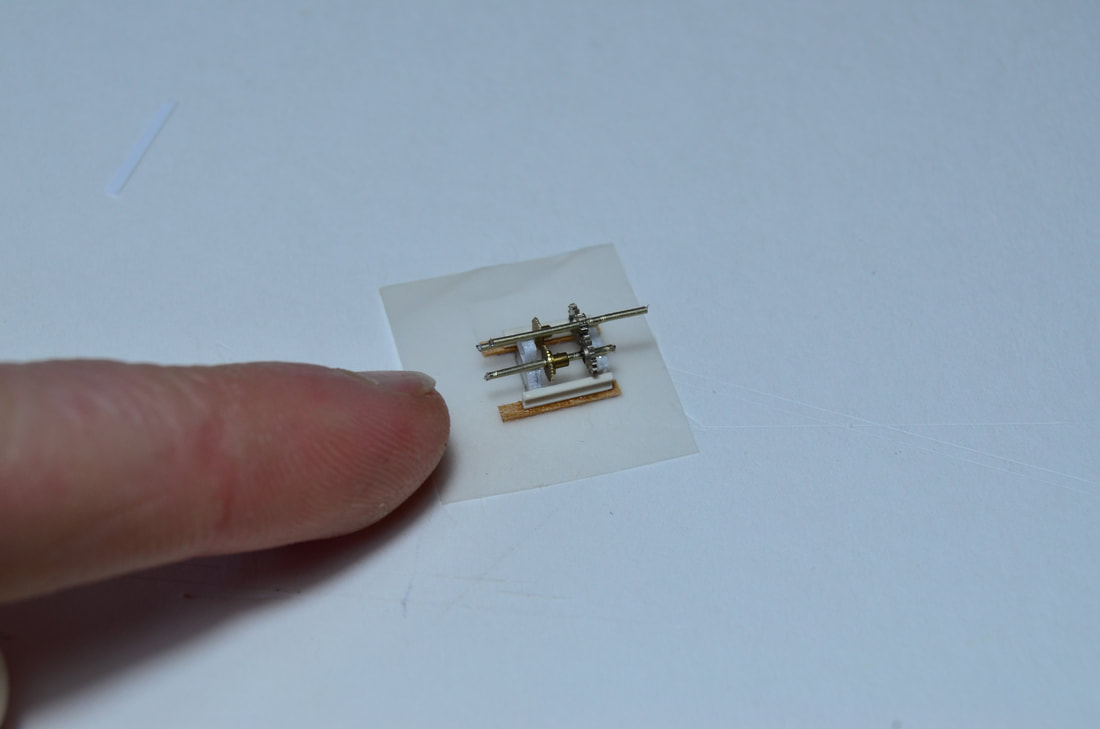

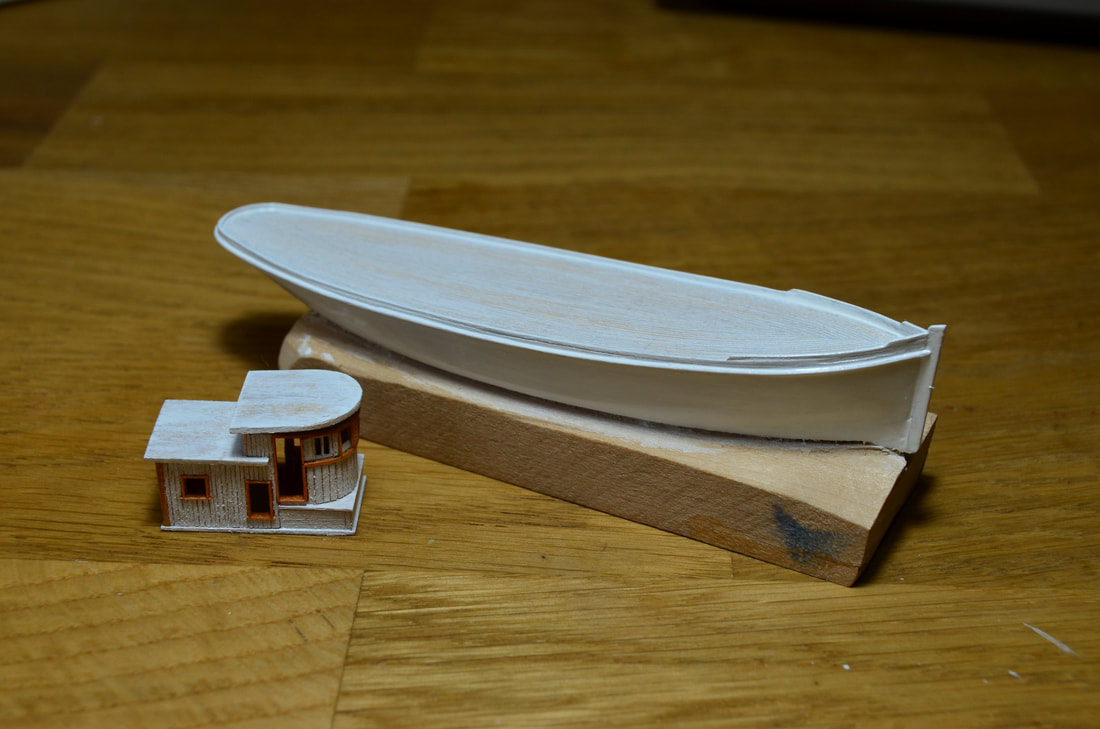

Snow fell yesterday and I watched the big fluffy flakes falling to ground, happy to be warm and cozy and sitting in front of my active little boatyard, the construction of my small fleet of Chesapeake boats progressing everyday. The F. D. Crockett has gotten a few coats of paint and I began installing the railing. It's a time consuming task accomplished by hand drilling tiny little holes in the bulwark with a 0.3 mm drill bit. I then insert the vertical stanchions and cut them to length, using a strip of card stock (a hair less than a millimeter in width) and some flush cutting nippers. The wooden railing, made of basswood, is less than a millimeter wide, and I had to cut it to shape it and carefully glue it to the tips of the stanchion posts. The round stern proved difficult and is fabricated from a few pieces of wood scarfed together. Once it was done, I gave her a nice coat of paint and set her aside to work on the next boat. I was eager to make a little progress on the Hooper Island Dovetail, and continued by installing the ribs on the previously carved out hull. The deck was laid on as one piece, with the cockpit and cabin space cut away, and I gave her a fine, wood rub-rail all the way round. The cabin was fabricated from .5 millimeter basswood strips (part of my stock of wood that my lovely husband machines for me from time to time). It was built from the floorboards up and is completely open in the interior. With a couple coats of satin white paint (we don't want shiny work boats), she was as pretty as a new penny. Waiting for paint to dry can nearly drive me nuts and while my Crockett and Dovetail, got one super fine coat of paint after another and were placed high up on the shelf out of the dusty boatyard, I had to get busy on another boat. When I visited Chesapeake Maritime Museum in St. Michaels Maryland, I was inspired by their Oystering on the Chesapeake exhibit in which the E. C. Collier is permanently displayed. You can board the boat and listen to the voices of watermen pulling up the dredges and sorting the oysters. Everything is there to see, the motor driven winder, the steering wheel with exposed gears, the dredge baskets, etc... The deck is warn and used, and you can observe the simplistic but rugged way in which a 107 year old skipjack was built. It's a huge inspiration to have access to exhibits like this, accessible to the public. So, I started building my miniature E. C. Collier by marking off the block of wood. I carved her shear first, then rough cut the shape of the hull with a handsaw before carving the shape of the hull. I made sure to mark off the chine were the cross planked, dead-rise bottom would meet the sides. Once, I got the shape of the hull just right, I added the bulwarks, leaving space for the dredge rollers on each side. I etched the deck planking into a piece of .5 millimeter basswood pre-cut to fit the deck and attached the long bowsprit support, unique to boats of the Chesapeake, on which will be the attractively painted trailing board with the name. Next came the railings, fabricated in the exact same method as the Crockett and then the sampson post, forward hatch, winder motor box, central hatch, main cabin and stearing box. One of the most important features on the Skipjack is the winder. This machine was used to raise the dredges that scrape the bottom of the Bay for oysters. Being in Switzerland, the watch making capital of the world, I've accumulated lots of watch gears and used them to represent the winder gears. Fabricating this tiny feature took the most part of the day. I gave it a weathered coat of paint and glued it in place on-board. One part of the boat that I was very proud of accomplishing was the rudder and I haven't painted it yet, since I wanted you all to see how it's built. The rudder is wood and their are two flat metal straps that wrap around the forward edge of the rudder creating a half hoop. On the transom I inserted to metal wires bending them at ninety degrees and lowered the rudder down and in place, just like on a real boat. It actually moves!

So here is the big question for you guys. I will paint the rudder white as was typical and the hull will get a weathered appearance, but should I put another coat of paint on her hull? I'm scared to make her look too clean, she is a work boat after all! Well that's all for now. Be sure to stop by in future to catch up on my winter project in my mini boatyard...next up, the Bugeye, Edna E. Lockwood. Winter is in full swing and most boatyard, especially in cold climates, have seemingly closed down until the fist sign of Spring, when boat owners once again start itching for the wind in their sales. But, deep in the heated shops of many yards work continues, new projects are started, and all preps are made for Spring launch dates. Here, in my mini boatyard, work too rolls on, and I needed a good project to distract me and keep me going through the long winter months. After much debate and struggle over the perfect scene in bottle to build, I turned to the Chesapeake Bay and the area where I grew up to be my inspiration. I've visited nearly every maritime museum on the Bay, lived and cruised upon her waters on our forty foot sailboat, and studied the unique crafts that hailed from there. She holds an impressive past, and I felt it was time to celebrate one particular and historically significant side of the Bay, the watermen of bygone days, who year round worked, struggled, and survived on all that she had to give. Remember, it's winter...well imagine being out there on those wooden skipjacks, deadrise work boats, or small log canoes one hundred years ago, scraping oysters off the bottom...the north wind blowing, choppy waves splashing over the rail, and frozen creeks making just getting in and out hard. So, my idea is to show the scene of the watermen working and the boats they used. I needed a time period that would allow me to show a diversity of vessels of the Bay during a period in which they were working all together. I chose the 1930's. By then, the deadrise powerboats filled the harbors and buyboats were making their rounds, collecting oysters from hand-tongers who preferred selling them on the spot, instead of wasting precious time running back to harbors to unload. But those glorious sailing crafts, the bugeyes and skipjacks were still making there turn on the Bay, dredging the bars for oysters. My scene will be comprised of four different vessels, all of which are boats that still exist...yes the jewels of the bygone era that have been saved by museums, so future generations can enjoy them! The first is the F. D. Crockett of the Deltaville Martime Museum, of which I am very familiar with having worked in Deltaville for five years. I watched her transition from a barely floating hulk, to what I consider, the most elegant of the still remaining buyboats. She is one of two remaining log bottomed buyboats and was built in 1924 by Alex Gaines of Dare, Virginia. The second boat I chose to build was the Hooper Island Dovetail (also known as a Draketail). These slick deadrise workboats were built for oyster tonging and crabbing and have a unique rounded and sloping transom. Dorothy Lee was built in 1934 by Bronza Parks and has been recently donated to the Chesapeake Maritime Museum in St. Micheals. The third boat I will be creating is a Skipjack based on the E. C. Collier, built in 1910 at Deal Island, Maryland. The E. C. Collier is a permanently fixed exhibit at the Chesapeake Maritime Museum. The final boat, and most impressive, that I will be including in the scene is the Bugeye, Edna E. Lockwood. The Edna E. Lockwood was built by John B. Harrison in 1889 and is the last existing workboat of her kind. Like the Crockett, her bottom was constructed of nine logs and she is currently be expertly cared for by the Chesapeake Maritime Museum in St. Michaels. To begin my project, I spent a few weeks researching full time the four boats mentioned above. I'm lucky to have a great library of Chesapeake books and grateful to authors like Brewington, Chowning, and Burgess who have compiled photos and texts on the active oystering years on the bay. Plans and images were gathered from many different sources, and I scoured the photographic onilne archives of various institutes. The first ship I started on, was the F. D. Crockett. To date, I've carved her hull, and fabricated the pilot house. The pilot house is completely open and has an interior dimension allowing light to pass through the windows. With one coat of paint she is really coming along nicely. I'll be fabricating the little doors next and then it will be on to the railings, rigging and deck furniture. While, the coats of paint dried on the Crockett, I got busy working on the Hooper Island Dovetail. It's just a start but, she's coming along nicely. I've carved the exterior of her hull, then gouged out the interior down to a millimeter from the hull bottom. Once everything was sanded smooth a began laying the floor boards in place. Each floorboard is just a hair over a 1/2 of a millimeter wide. Next I'll be adding the deck, rails and cabin. So, what progress will I be making next...well, you'll just have to wait and see! Make sure to keep stopping by periodically as I will be updating the status of this project here on my blog. Thanks for reading!

The evolution of my ships in bottles:Over the past 8 years I have fabricated nearly 100 ships in bottles, taken thousands of pictures, written articles for ship in bottle associations, had numerous articles in the press, constructed SIBs for company promotional purposes, displayed my artwork at artisan and craft expos, and even got myself on television. I hope to be able to organize a great deal of this information on this site for you to access and enjoy. My Work Now: Building ships in bottles is an ongoing and ever evolving process. My selection of materials are no longer dictated by ease of use or accessibility, but by their durability, quality level, and exactitude in representing the parts of a real ship. I now fabricate every ship in bottle based on available plans combined with images of the boats, as well as descriptions and measurements. A great deal of research and planning goes into each ship in bottle, sometimes taking up almost as much time as the fabrication. Its stages of construction are carefully planned before I even pick up my tools, so I can feel confident that mistakes won't be made and I am sure of the layout of every part of the ship. Practice makes perfect, and this can't be more true in my line of work. Over the years I have trained my hands, eyes, and mind to be as accurate, clear, and as steady as possible. I've learned to see errors and make measurements within a tenth of a millimeter or smaller in accuracy, while being able to handle and fabricate tiny pieces of the minute scale. I've developed my skills in handling my basic tools, various chisels, blades and scalpels, hand saws, tweezers, and work with both my right and left hand. And the overall result that I have always desired to achieve, is to give my miniature ships a life inside a bottle and create an atmosphere of a real ship at sea. My Work for the Future

My hopes for the future of my craft are to experiment with more types of woods in the actual fabrication of the ship itself. And, develop new and improved ways of constructing and representing the portions of the ship. I also hope to create more complex and active scenes in bottles that can tell an even larger story or a portion of a ship's history which may mean working in larger bottles. I am as always taking commissions on all sorts of ships in bottles from small open dinghies, classic and modern yachts, power boats, to complex intricate scenes of the square riggers of old. Feel free to contact me with any requests, ideas, or questions for future projects! |

Details

AuthorHeather Gabrielle Rogers: Shipwright for bottled miniature models. Archives

March 2018

Categories |

RSS Feed

RSS Feed